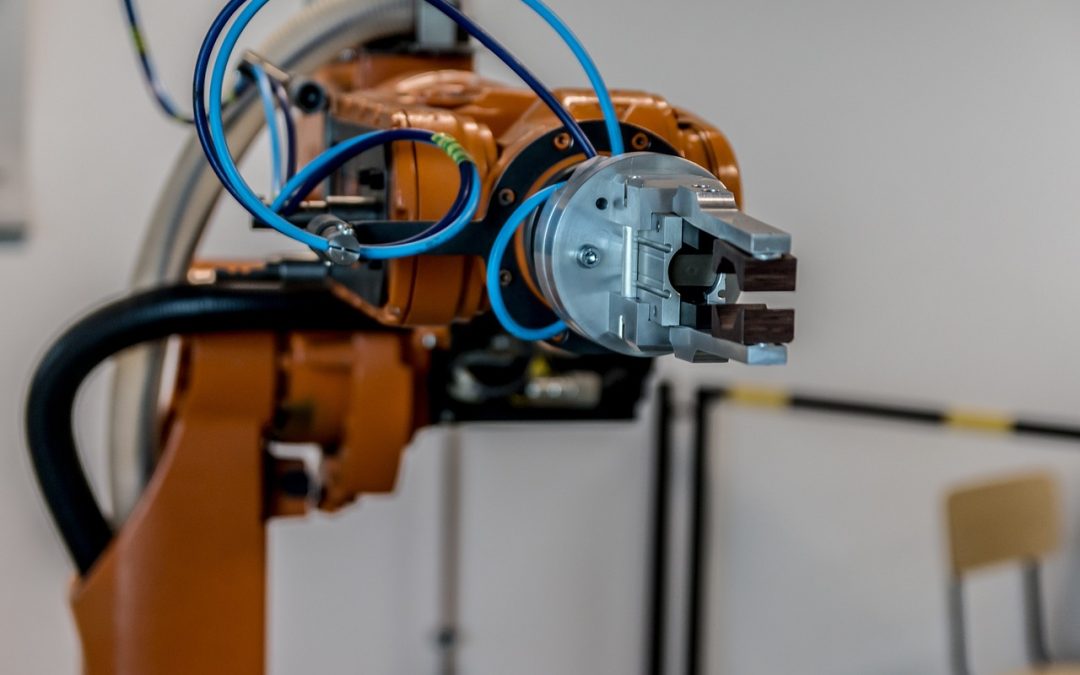

Automation has been a much-talked about topic in the sphere of literature, art and media, where it is depicted as the picture of a gloomy world where machines have the upper hand. Nevertheless, industrial automation is the biggest instance of this fast-paced reality—which not only proves to be faster, yet also kills costs dramatically and ensures safety.

How bright is the future of automation?

Automation looking at the future of manufacturing needs to be aware not only of what is happening within the factory but as well of what is happening on the outside of it. In this blog’s article, we will focus on the lights down operation and discuss how it is future-proofing automation.

Lights-Out Manufacturing: A Game-Changer in Automation

In the mid-50s “Autofac” by Phillip K. Dick not long ago was a dystopian scenario of planet resources’ monopoly by self-replicating machines. Today, the lights-out manufacturing, where robots work without any human aid, is such a reality in some manufacturing facilities. This production process especially at the beginning is cost intensive but presents several advantages that makes it indisputable trendsetter in automation.

Advantages of Lights-Out Manufacturing

Robots can perform continuously in contrast to human beings who at some point may get tired, bored, distracted, and ill. This consistent performance translates to automation efficiency, a factor that allows manufactures cope with higher demand and still sustain quality.

On top of this, lights-out manufacturing abolishes the costs of human products such as lights, heat, ventilation, and air conditioning, consequently producing in savings of big energy and operation costs.

Real-World Examples:

FANUC, a Japanese robotic company operating lights-out, has been running its Oshino FANUC factory since 2001, with the robots becoming self-replicators during this period. They are able to replicate at a rate of 50 per 24 hours. The whole factory of Philips in the Netherlands is almost completely robotized and annual production of 120 machines can reach up to 13 million razors. The results of these cases demonstrate, though, the viability and profitability of manufacture without people working.

The Future of Automation

The automation of the future is about machines that will be more smart, flexibles and intelligent. It will be the progress in artificial intelligence, machine learning, and robotics that will bring the possibility of automating functions that but more lately had been the exclusive realm of the human workers.

Possibly the next few years will be witnessing that a variety of sectors as well as jobs were affected by automation. From artificial forming of things and transferring them to healthcare and finance, many jobs will be replaced by technologies takeover partially at least. This does not have to mean that humans will be totally substituted by technology but it will be changing the way we work and thus the workers will do new jobs or perform a spectrum of duties.

Improving Product Lifecycle Management

Automation in factories can help with resolving both emerging and existing challenges. For example, the utilization of much more automation can also be quite a strategy to make the processes more efficient, eco-friendly, and less complicated.

However, the production of goods and services can certainly be accompanied by a significant number of positive moments for the industry. Besides, if we look at it from the point of the view of macro side, one major advantage is that automation is achieved through process improvement. When a person thinks about the manufacturing industry there is a tendency to imagine a robot taking off a repetitive task, regardless if it is a medium sized or a large company.

The responsibility doesn’t stop after the tasks are automated, neither all the work is done. The presence of various change management adjustments will be feasible, which may include some insignificant modifications or even major transformations of the process of the whole business.

What this mean is that manufacturers may be able to enhance the speed of repetitive and regular movements of robotic arms as well as making them more effective. Furthermore, integration of data from factory floor robots with data streams from other systems in the factory may, for example, lead to detection of production imbalances or identification of any duplicating or siloed processes, and consequently help the management develop effective strategies.

What comes as the result is the so-called product lifecycle which, as an asset, may include anything from product design to testing and development processes. Implementing a good production lifecycle program can reveal problems and make efforts towards improving any production processes on the shopfloor.

Human Factor in Automation

In contrast to the negative attitude of automation to create jobless society, machines running with no human involvement can, however, positively influence job-security of employees by offering them more challenging jobs. On the one hand, bots become the irreplaceable assistants in recitation and hazardous works, but human workers can then be re-trained in roles that require abstract thinking and complex problem-solving skills. Since the line of work is progressing fast, employees consistent revision process is vital for remaining in the know-how of the already developed market.

Automation would have imminent implications for labor forces

Automation’s future has a bright outlook, with the technology evolving and growing with the introduction of lights-out manufacturing, that allows it to be integrated in companies of all sizes. Human beings are such that no matter how automation is improved, always there will be a high demand for well-informed personnel to master the machines, set them up, monitor their performance, and do the required maintenance.

Through this automation and investing in talks about educated and trained workforce, companies will be able to prepare for the future that has a lot of automation.

Conclusion:

On an ending note, the car industry game-plan has never been more promising than it is in current times.Lights-out production provides for enhanced profitability, greater productivity as well as cost reduction as well as ensured safety in industrial environments. Embracing automation and spending money to educate and train the workforce achieve combining the automated future. This is one of the most important factors for a company to ensure their competiveness and widespread existence.