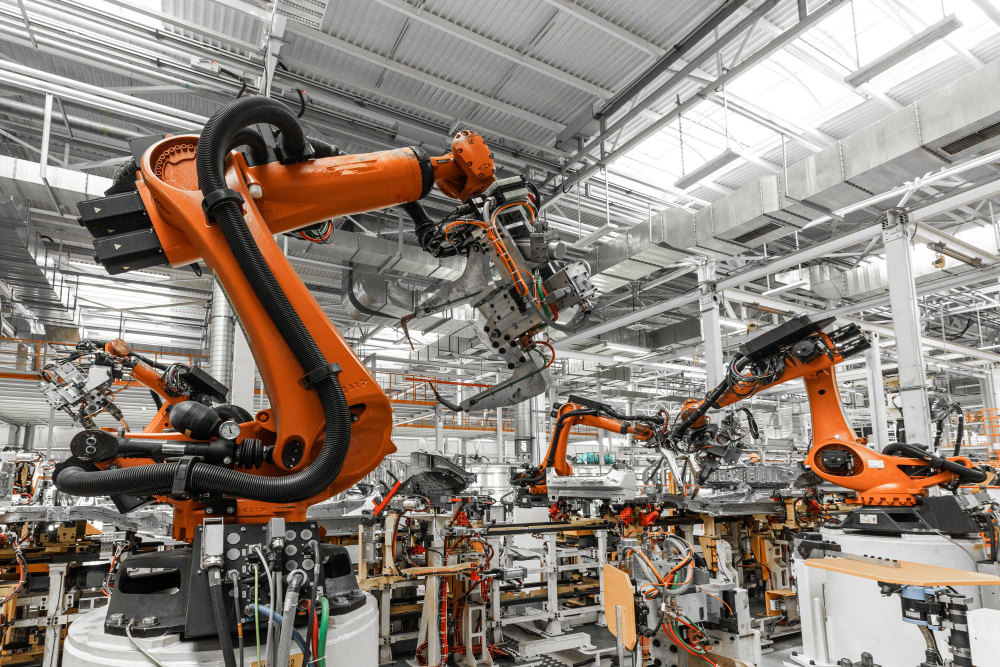

As the pace of businesses is rapidly declining, automation has become one of the biggest game-changers, having a revolutionary impact on the way businesses work and increasing productivity by a mile. Industrial automation refers to applying robots and latest technologies to automate tasks that were previously performed by humans. Let us briefly discuss 7 ways how automation increases productivity in various sectors.

How Automation Helps in Improving Productivity?

In this post we are going to explain how businesses can achieve better productivity through automation.

1. Streamlining Operations:

Industrial automation improves productivity, simplifies complex processes by automating those tasks that are repeated, which are generally assembly lines and quality control check, among others. Manual capability is diminished as the production processes go on, so, such processes become more efficient and error-free. Reports have been highlighting that the productivity of businesses, which are adopting automation, can go up to 40%.

2. Enhancing Accuracy and Quality:

Automation increases productivity by providing accurate data about the processes being followed in plants, resulting in better quality products. Automated systems are in a position to reduce serious mistakes and surprises from recycling activities. This increases customer satisfaction and reduces waste generation, which helps companies achieve more profits.

3. Optimizing Production Planning:

This self – taught software uses data in the moment to increase production schedules and utilization of available resources. Production planning strategies including forecasting demand and suitable production adjustments may limit downtime and maximize output at the same time. Research indicates that automation can increase production planning accuracy up to 20%, which is 100% better than the human-planning level. Which means that automation helps in improving productivity by increasing production planning accuracy.

4. Improving Workplace Safety:

Industrial automation poses as a solution to makes the workers avoid the duties which are undertaken in a hazardous environment, thus the chance of a workshop accidents and injuries reduces. Robots and automated machinery may replace people in dangerous tasks and those requiring strength and resistance to smoky environment. This results in safer workplaces and a system where fewer workers are ill or injured while working, and thus, there is less expenditure on workers’ compensation insurance.

Check out: The Bright Future of Automation: A Look into Future of Manufacturing

5. Increasing Speed and Efficiency:

On the other hand, this automation increases productivity by working at lightning speed and can work during the day as well as at night without any slowdown or strain. Time is the essence of this process. Therefore, companies can quickly fulfill customer requests. Studies have shown that automation can increase the speed of production by up to three times, which is a good achievement when you consider manual processes in comparison.

6. Enabling Predictive Maintenance:

Automation technology is used in transport to follow real-time performance of the equipment and is able to indicate any issues before it causes failures. Planned maintenance with predictive strategies help business increase machinery uptime and at the same reduce the cost of maintenance while extending the life of the equipment at the same time. Research indicates that predictive maintenance can see a boost in equipment uptime by up to 45% rate.

7. Empowering Skilled Workforce:

Industrial automation, especially robotics, plays an important role in freeing of skilled manpower from monotonous tasks which can be performed by machines thereby mediating efforts on critical and value-added activities like correlation and process optimization.

This not only heightens employee job satisfaction but also provides a place for innovation spirits to flourish. Research showed that the employees who took a greater sense of ownership in their work were 20% more productive than the employees who were disengaged.

Therefore, businesses and industries can achieve better productivity through automation. These seven methods outline how automation increases productivity and efficiency.

Conclusion

Lastly, it could be asserted that industrial automation is transforming companies through increasing labor productivity, leading to improvement in the product quality, making working conditions safer and empowering the staff.

While automation is providing operations streamlining, increased accuracy, optimization of production planning, workplace safety improvement, productivity raise and effectivity increase, predictive service and workforce qualified personnel empowerment it is a driving force that makes today‘s global marketplace to be both sustainable and competitive.

The acceptance of automation is not just an alternative: rather it is a matter of strategic importance for businesses which want to remain competitive in the digital era.